Introduction:

Assam, known for its rich tea plantations, provides an abundant source of tea waste, which is used innovatively in the production of natural dyes. The use of tea waste as a dye is part of the sustainable practices of utilizing agro-waste to reduce environmental impact. Tea waste dye yields a range of brownish and earthy tones that reflect the natural beauty of the North-Eastern landscape. This natural dyeing process not only enhances the aesthetic appeal of handloom products but also plays a significant role in promoting eco-friendly textile practices across the region.

Description:

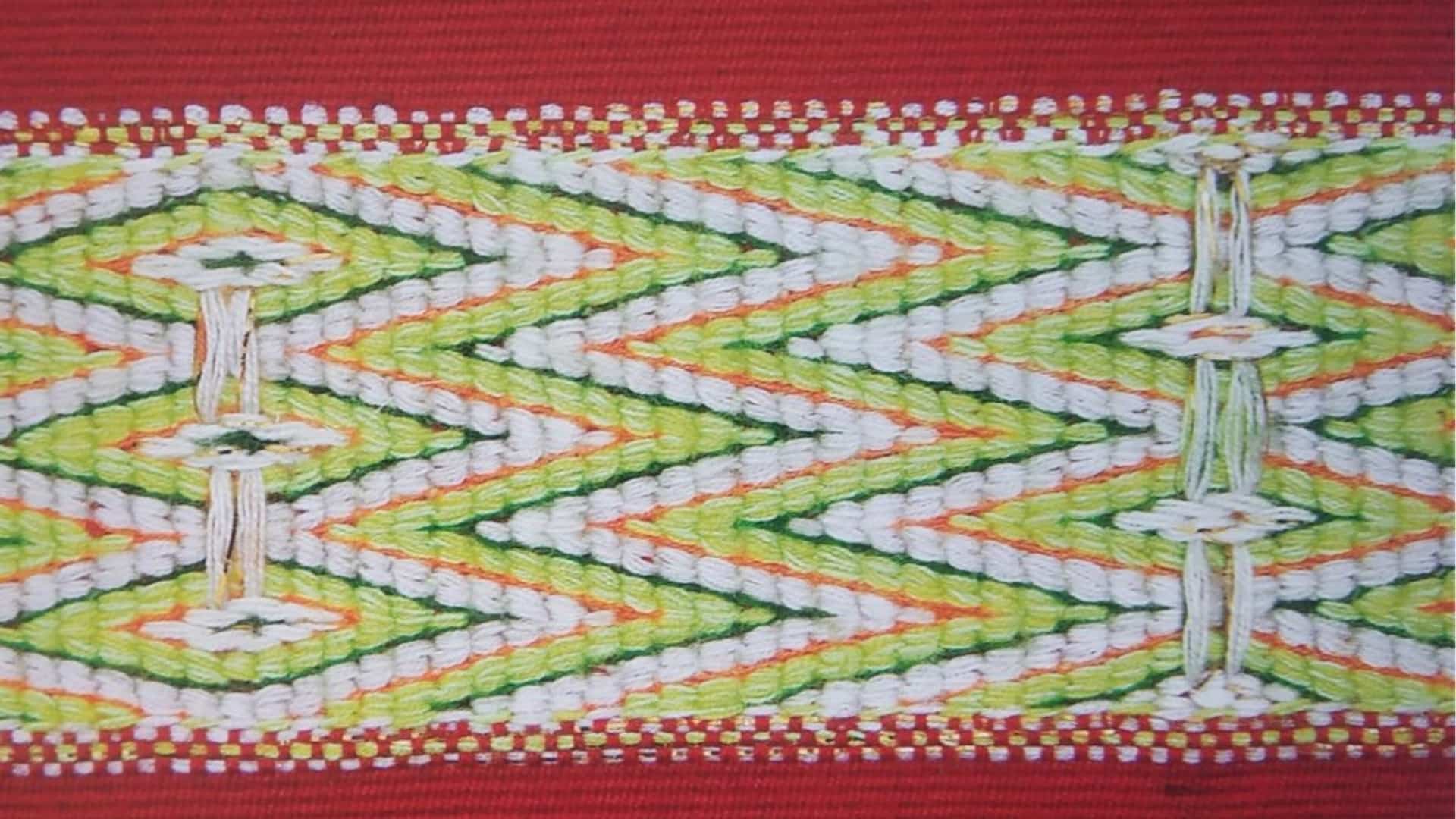

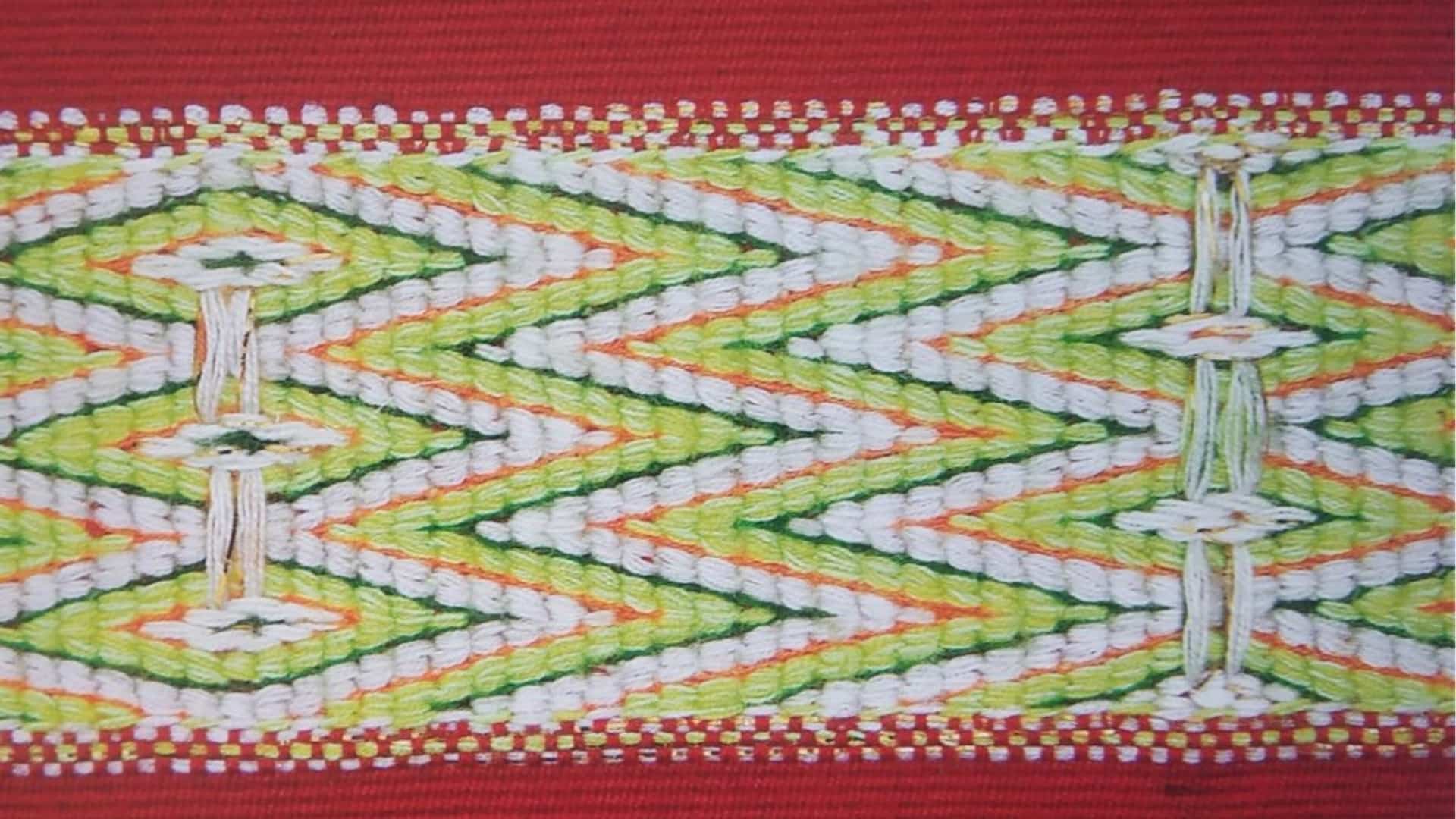

Tea waste dye is obtained from the leftover tea leaves and stems that are discarded after the tea-making process. In Assam, where tea production is a major industry, these wastes are repurposed as a natural dye, reflecting the state’s deep connection to both tea and sustainability. The extraction of dye from tea waste involves boiling the waste in water to create a dark brown liquid. This liquid contains tannins, a natural substance found in tea leaves that binds well with natural fibers such as cotton, silk, and wool. Tannins play a crucial role in enhancing the dye’s adhesion to the fabric, making tea waste dye relatively colorfast compared to other natural dyes.

The shade produced by tea waste dye varies depending on the concentration of tannins in the tea and the duration of the dyeing process. Lighter hues can be achieved by shortening the dyeing time, while darker and richer browns develop with prolonged exposure to the dye bath. Additionally, the use of different mordants, such as alum or iron, can modify the final color. For example, iron mordants may produce deeper, more subdued shades, while alum preserves the natural brown of the tea dye.

In the traditional handloom sector of Assam, tea waste dyeing is a process that honors both the natural resources of the land and the artisanal techniques passed down through generations. After the dye is prepared, the fabric is soaked in the dye bath for a few hours to ensure even color distribution. Once dyed, the fabric is rinsed to remove excess dye and then dried in the shade. This process not only yields beautiful earthy tones but also contributes to the zero-waste movement by reusing what would otherwise be agricultural waste.

Tea waste dye is particularly valued for its environmental benefits. Unlike synthetic dyes, which can be harmful to both the environment and human health due to the chemicals involved, tea waste dye is entirely natural and non-toxic. Its production does not require any additional chemicals or resources, making it a highly sustainable option for eco-conscious consumers. Furthermore, the use of tea waste as a dye helps reduce the environmental burden associated with tea production, as less waste is discarded into landfills.

The growing popularity of tea waste dye in Assam’s handloom industry also aligns with the global trend towards sustainable fashion. Consumers today are increasingly aware of the environmental impact of their clothing choices, and products made with natural dyes like tea waste appeal to those seeking eco-friendly alternatives. By supporting artisans who use tea waste dye, consumers are not only embracing sustainable practices but also helping to preserve the rich cultural heritage of Assam’s textile industry. This natural dye, with its deep connection to the land and its people, continues to inspire both traditional artisans and modern designers alike.